Window design

Countless options with RAL colors and laminations

RAL colors

All Gemi windows and doors are available in any RAL color. The coating process offers:

- Intensive, fade-resistant colours

- Comprehensive RAL colour palette

- Various gloss levels

- Robust and highly weather resistant

- Easy to clean

- Sustainable and environmentally-friendly

Laminations

Laminate (often called “rigid thermofoil” or RTF) is a rigid vinyl film composite that meets the highest demands in terms of design, quality and performance. 3D Laminates offer you the design flexibility of contoured shapes and seamless soft edged components. They are offered in highly realistic woodgrain patterns, metallic, abstract patterns, and solid colors in various finishes and embossing.

Check out full lamination range

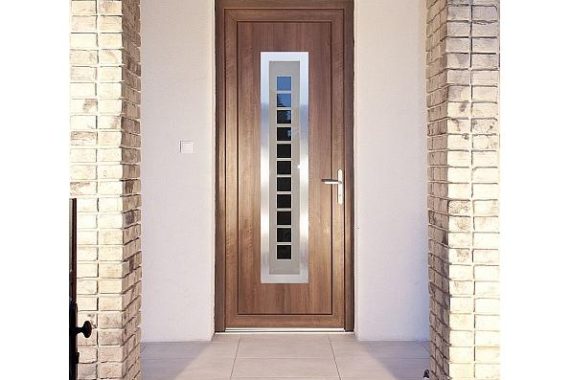

Door design

Plastic infills finishes

GAVA Plastic Door Panels are manufactured by a system that uses vacuum thermoforming PVC boards and thermal insulation materials.

The actual design is shaped in relief on a solid metal die, with full, glass surfaces located in the inside of the rustic or modern relief.

We use PVC material developed, tested and designed exclusively for production of door panels by the world’s leading plastics manufacturers. A cold roll laminator coats PVC boards, besides those in white, with “plastic film” while using so-called “cold plastic” backing plates that absorb substantially less heat radiation.

When thickness is greater than 36 millimeters, Core F is recommended to significantly reduce the adverse forces acting under different climatic conditions on the door all year round.

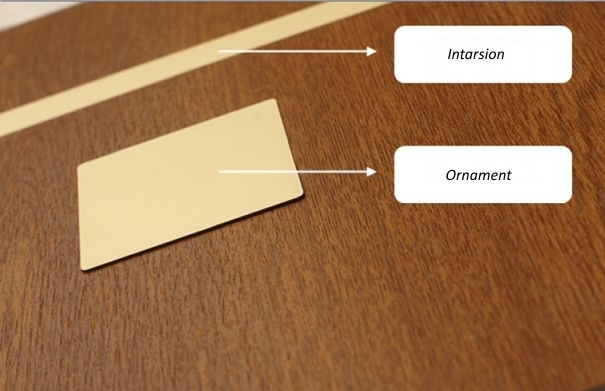

High pressure laminate finishes

HPL cannot be thermoformed and so are used for producing flat designs. These are formed with a combination of glass surfaces and metal applications or inlays. All designs are available in a broad range of different hues.

HPL (High Pressure Laminates) are a resin-based material reinforced with cellulose fibers that are manufactured under high pressure and at high temperatures. Harder and with a lower thermal expansion than PVC and aluminum, in contrast to them it is partially hydrophobic. When thickness is greater than 36 millimeters, Core F is recommended to significantly reduce the adverse forces acting under different climatic conditions on the door all year round.

Detailed catalog

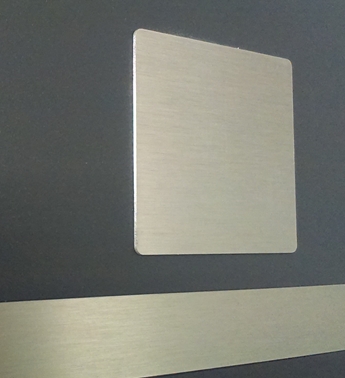

Aluminium infills finishes

The design is characterized by sophisticated simplicity and purity in shapes and lines. Creative motifs can be formed with solid or glass surfaces, relief or flat-bar profiles, milled grooves, stainless steel applications or inlays. The engraved color surfaces are encrusted with jewels set in the door.

The aluminum door fitting properties described earlier provide options for an overlapping door-leaf design – FD, while being the ideal product for demanding customers.

GAVA Aluminum Door Panels use a metal surface plate made of aluminum and magnesium alloys. They are distinguished by their high strength, with no change in internal stress even over a long period of time. Color is applied to surfaces by powder varnishing before the lacquer is cured in an oven.

GAVA Aluminum Panels are noted for their precision machining, using the latest, cutting-edge technologies such as laser cutting, CNC milling and welded frames produced from our original relief profile.

When thickness is greater than 36 millimeters, Core F is recommended to significantly reduce the adverse forces acting under different climatic conditions on the door all year round.